6300 Commercial and Industrial

The unique configuration of these Operators allows the gate arm to rotate from underneath the Operator, enabling the arm to attach to the bottom rail of the gate, were it is virtually unseen from outside the gate. The fully enclosed Operators prevent water from contaminating the output shaft, bearings, and electronics. Additionally, the frame is built from G90 galvanized steel to prevent rusting. These Operators can be installed directly on a concrete pad, or post-mounted to meet any installation requirements.

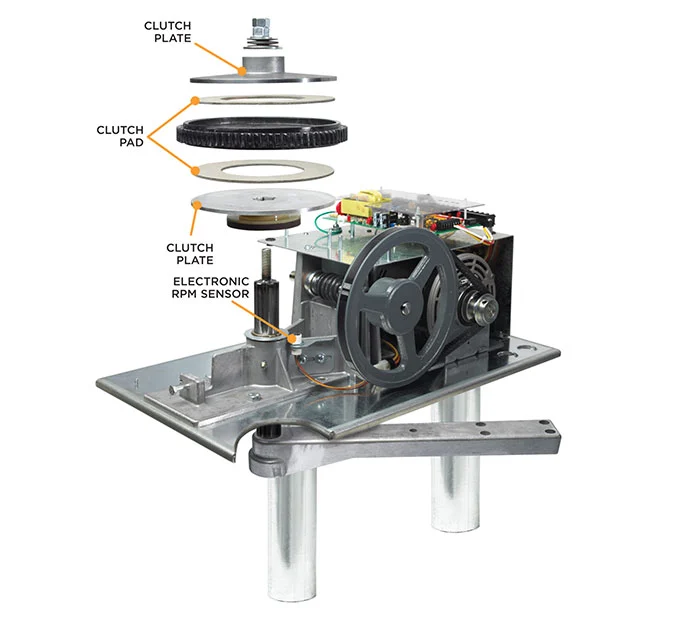

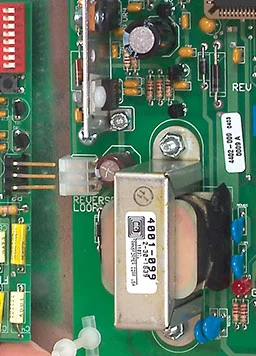

With safety in mind, these Operators contain an electronic and mechanical inherent reverse system for two methods of obstruction detection. The automatic electronic limits, along with the microprocessor-based electronic control board provide advanced features not typically found in Operators in this class.

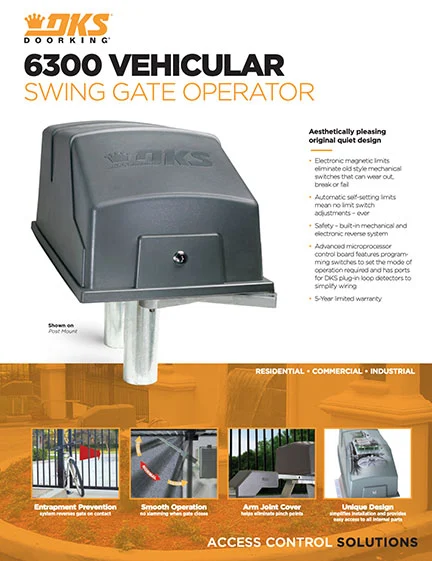

Aesthetically Pleasing – Original Quiet Design

The 6300 series operators are designed to operate vehicular swing gates in residential, commercial and industrial applications. These operators are designed so that they can be either pad or post mounted without any costly and time consuming field modifications. You need to specify which mounting method when ordering. The unique design of these operators allows the gate arm to be attached to the bottom rail of the gate. This eliminates the need for any brackets to be welded to the face of the gate and creates an aesthetically pleasing installation.

Compatible with

Swing Gates

Versatile Mount on

Concrete Pad or Post

Low-Visibility Attachment

on Gate’s Bottom Rail

Applications

Product Features

Gate Configurations

Suitable for single or dual gate configurations.

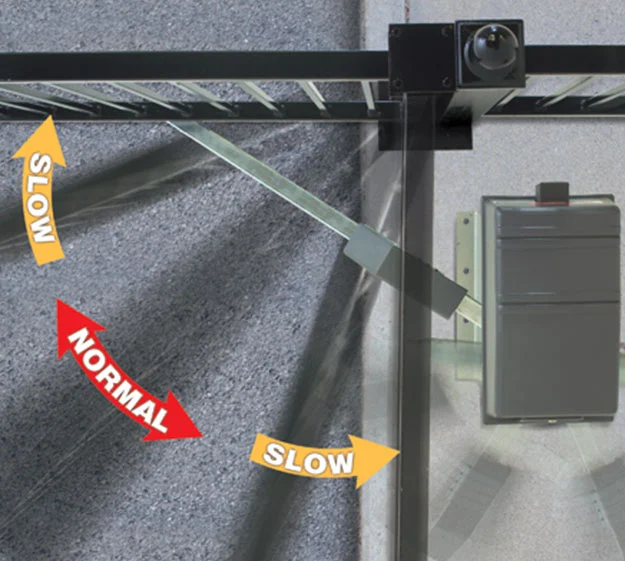

Smooth Operation

Soft Start / Soft Stop provides smooth gate operation.

Arm Joint Cover

Helps to eliminate pinch points and protects against harsh weather.

Loop Detectors

Easy plug-in ports for DKS Loop Detectors.

Entrapment Prevention

System reverses gate on contact to prevent injury and damage.

Unique Design

Simplifi es installation and provides easy access to all internal parts.

Technical Specifications

18′ / 22′ Maximum Gate Lengths

700 lb. / 800 lb. Maximum Gate Weights

Opens 90º in Approximately 16-18 Seconds

Optional Backup Power Inverters

1/2 & 1 HP Continuous Duty Motor

Specifications

Model 6300 with 1/2 HP Motor

- Maximum gate width 18-feet.

- Maximum gate weight 700 pounds*. (*Assumes gate swings level and is in good condition with properly adjusted hardware. Other external factors may affect the performance of the gate operator.)

- Swings gate 90 degrees in approximately 15-18 seconds.

- 1/2 HP continuous-duty motor.

- 115, 230*, 460* VAC. (*230 and 460 volt units use a step-down power transformer to achieve 115 volt operating voltage.)

- Class I, II, III and IV applications.

- Compliant with UL 325 and 991. ETL Listed. (Note: To be compliant with UL 325 and industry safety guidelines, additional Type B1 and/or Type B2 entrapment protection devices need to be installed with this gate operator. Your professional DKS system installer can provide you with more details on these devices and on current industry safety standards.)

- Maximum gate width 22-feet.

- Maximum gate weight 800 pounds*. (*Assumes gate swings level and is in good condition with properly adjusted hardware. Other external factors may affect the performance of the gate operator.)

- Swings gate 90 degrees in approximately 15-18 seconds.

- 1 HP continuous-duty motor.

- 115, 230*, 460* VAC. (*230 and 460 volt units use a step-down power transformer to achieve 115 volt operating voltage.)

- Class I, II, III and IV applications.

- Compliant with UL 325 and 991. ETL listed. (Note: To be compliant with UL 325 and industry safety guidelines, additional Type B1 and/or Type B2 entrapment protection devices need to be installed with this gate operator. Your professional DKS system installer can provide you with more details on these devices and on current industry safety standards.)

Gate TrackerTM

Reporting output provides operator data to a DKS 1833, 1835, 1837 or 1838 access control system (requires 2358 expansion board)

Mechanical

- Self-adjusting, no maintenance magnetic limits.

- Overlap feature for dual swing gate operation.

- Designed with a built-in primary and secondary entrapment prevention system.

- Ports for plug-in loop detectors.

- Two convenience outlets.

- Fail-safe release.

- Tamper detect circuit.

- Gate tracker reporting output.

- Programming switches.

- Built-in reset switch.

- Built-in power On/Off switch.

- Primary reduction is provided by a pulley / belt driving a worm gear reduction system

- The 6300 rotates the gate 90° in approximately 16-18 seconds

- G90 galvanized steel frame to prevent rusting

- Two-piece articulating arm mechanical slow-start / slow-stop function

- Operator is pad or post mounted – specify which

- Keyed access is provided to release arm for manual gate operation in the event of a power outage

Electrical

- Auto-close timer (1-23 seconds)

- Gate overlap feature for bi-parting (dual) gate operation

- Simple connection for secondary operator in bi-parting gate systems

- Selectable shadow / reverse loop function

- Magnetic lock output

- Two 115 VAC convenience outlets for accessory transformers

Miscellaneous

- Environmental: 10°F to 115°F (-12°C to 62°C)

- Thermostatically controlled heater kit recommended for colder environments

- Operator requires monitored Type B1 and/or Type B2 entrapment protection devices

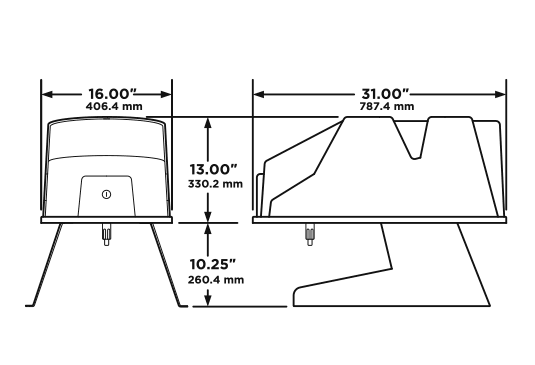

Pad Mount

Dimensions 16″W x 13″H* x 31 “D (operator only): * Pad mount adds 10.25” (260mm) to height dimension.

Weight Shipping weight approximately 120-160 lb (54-73 kg) depending on model and options selected

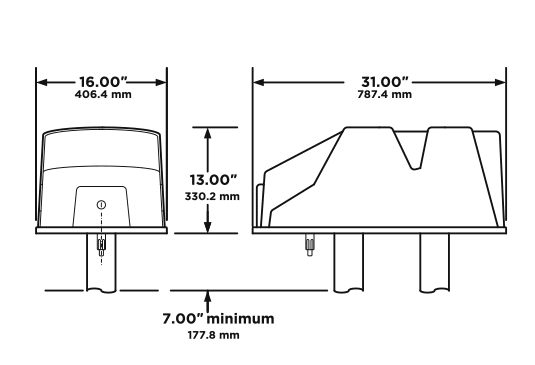

Post Mount

Dimensions 16″W x 13″H* x 31 “D (operator only): * Post mount operator height is adjustable by the installer

Weight Shipping weight approximately 120-160 lb (54-73 kg) depending on model and options selected

Tech Support

Find all the documentation needed to install, program, and operate your DKS product below.